CheckPoint creates perfect footprint for FPSO vessel

Champion & Petrobras operates a platform situated on a FPSO vessel (Floating Production Storage and Off -Loading), working at the Campos Basin in the southern Brazilian waters. An existing system of pneumatic pumps, operating for about five years, was pumping paraffin inhibitor. Breakdowns and repairs occurred far too frequently, and the related maintenance expense plus sourcing spare parts became troublesome and costly.

A solution by CheckPoint Pumps & Systems was supplied to tackle the daunting obstacles facing

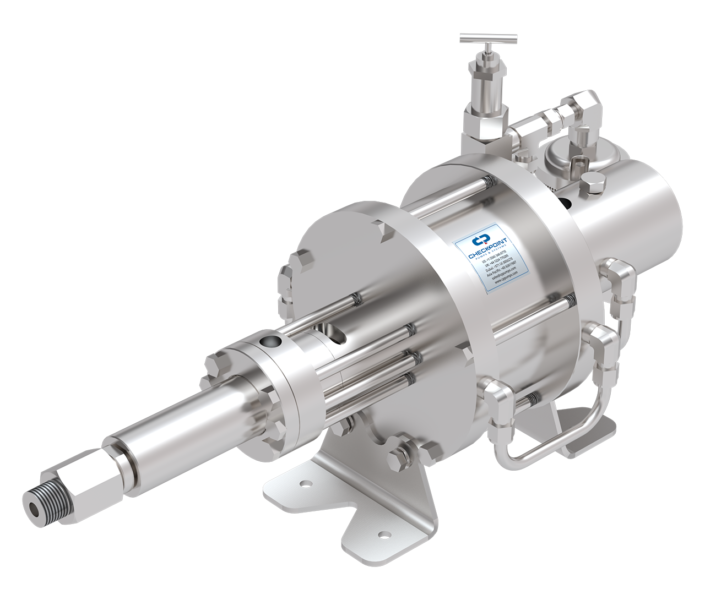

Champion-Petrobras. These units were to be located in the FPSO’s turret, which have a very constrained design footprint. H2S scavenger was to replace paraffin inhibitor, and it was required that ten different injection points be supplied by ten pumps. These pumps were to supply chemical at the rate of 100 LPH (24 GPH) against pressures of up to 185 kg / cm² (2700 PSIG).

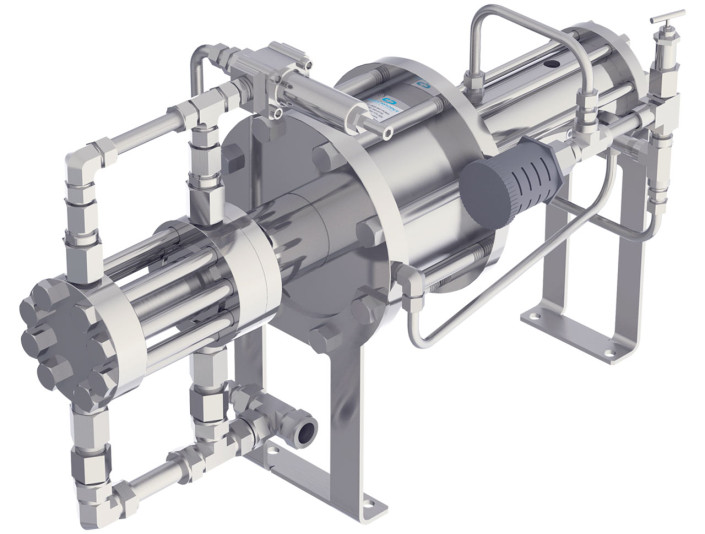

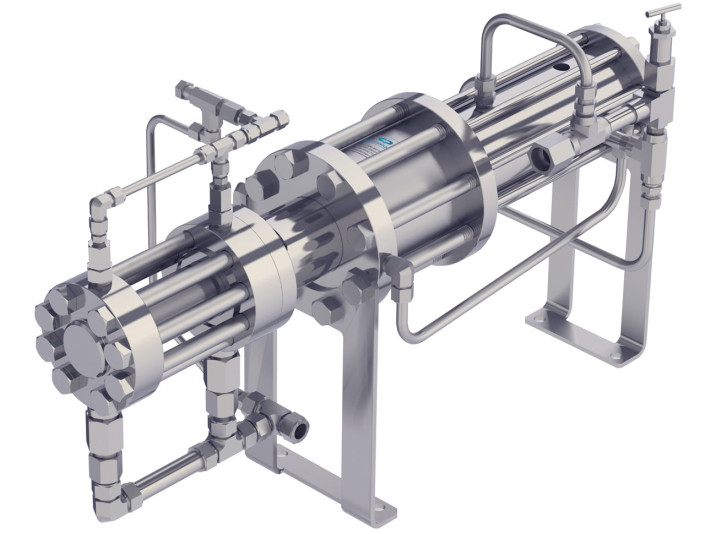

CheckPoint Engineered Solutions designed a stacked, five skid arrangement, with three skids along the bottom to support two skids stacked on top. This ten-pump configuration permitted agility in positioning the units on-site. Each two-pump skid could also be positioned independently anywhere on the vessel, offering maximum flexibility for future operations.

Each skid contained all the necessary components for optimum pump operation, as well as pressure monitors and pulsation dampeners to achieve a steady delivery of chemical – critical to H2S scavenging procedures. CheckPoint was able to supply the complete system 39 working days from order placement.

Ultimately, CheckPoint Pumps & Systems rapidly engineered an effective, quality solution meeting the needs of Champion & Petrobras.

Engineered Pneumatic Chemical Pump Systems

- Configured Design

- Minimum Footprint

- 10 Independent Injection Points