How Often Do You Repair Leaking Seals?

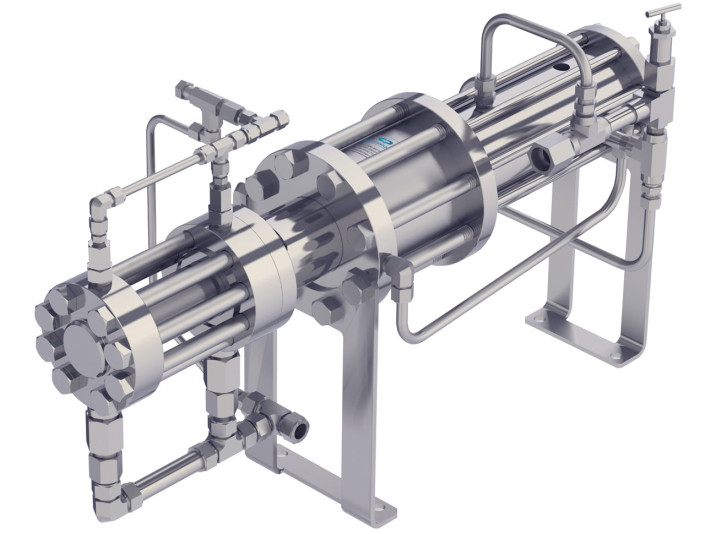

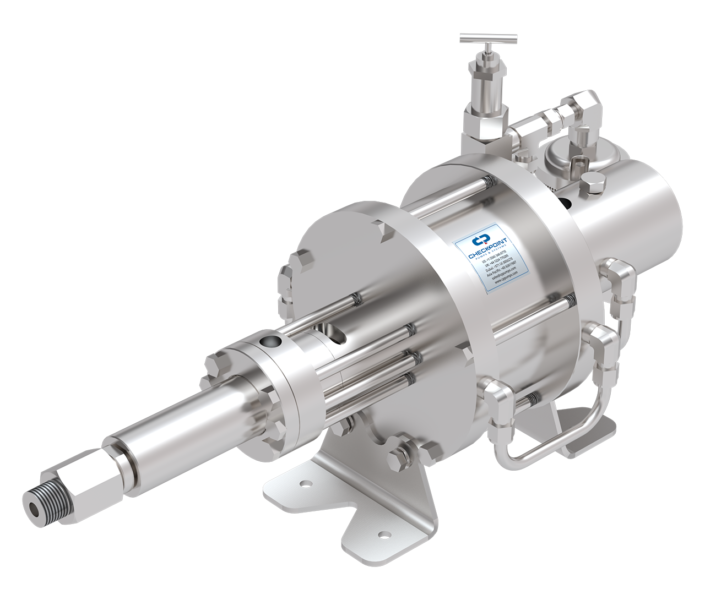

ExxonMobil Nigeria was using competitor pumps, and frequently encountered downtime due to seal leakage. The cost of spares and technician repair time affected their bottom line, and asked CheckPoint to provide a replacement system using EPDM (ETHYLENE PROPYLENE DIENE MONOMER) seals. The system is manufactured to inject 5 or 7 injection points on the platform with Corrosion Inhibitor. All pumps are CheckPoint Series 1250 gas recovery models with ¼” (6.35 mm) plunger and EPDM seal packages. The systems have integral 350 (1.325 m3) gallon tanks and panels which with Versa valves show immediate operational information to the operator.

The pumps can be collectively halted by the emergency shutdown facility, or individually shut down should they go over pressure less an operator error occurs with a closed inline valve. Such an error will be indicated on the system panel for the operator to see.

All CheckPoint products are manufactured from 316L SS, apart from the plinth (provided along with drip tray for all pumps) which is coated with 3 coats of epoxy paint off shore specification. The plinth is also supplied with a lifting beam and wire stops to lift into position on the platform.

Seal Leakage solution for corrosion inhibitor

- Bottom line continually impacted by downtime and repair

- CheckPoint’s EPDM – rubber synthetic seal stops leakage

- Choice of automated or manual shutdown