How Do You Ensure Your Carbon Steel Tank Is Protected?

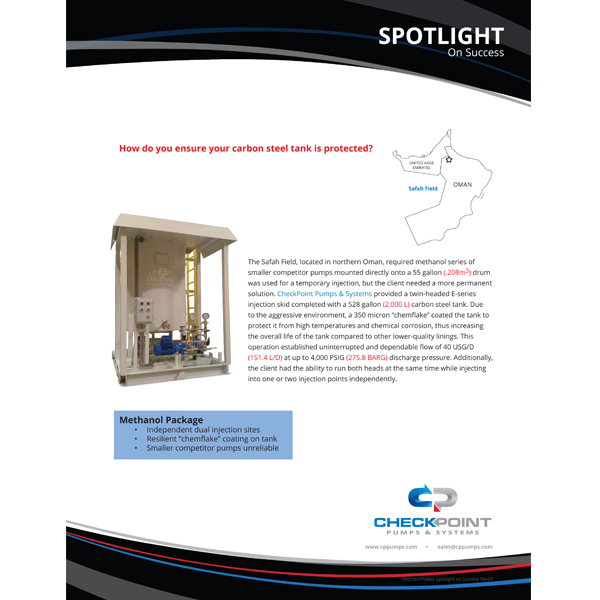

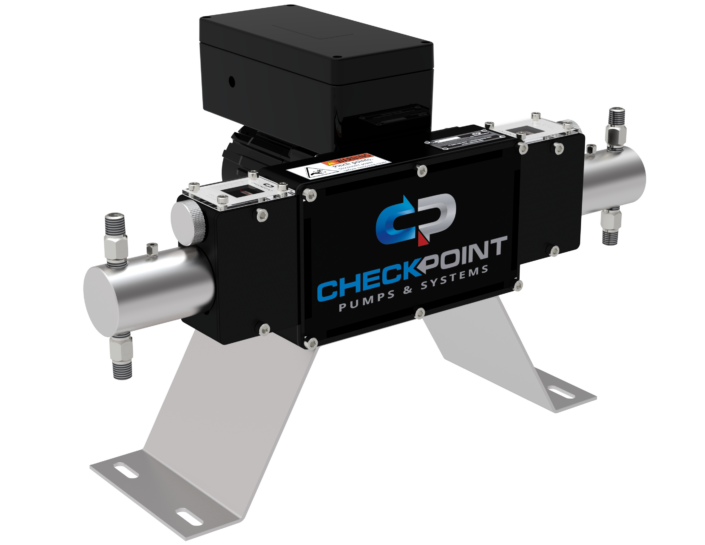

The Safah Field, located in northern Oman, required methanol series of smaller competitor pumps mounted directly onto a 55 gallon (.208m) drum was used for a temporary injection, but the client needed a more permanent solution. CheckPoint Pumps & Systems provided a twin-headed E-series injection skid completed with a 528 gallon (2,000 L) carbon steel tank. Due to the aggressive environment, a 350 micron “chemflake” coated the tank to protect it from high temperatures and chemical corrosion, thus increasing the overall life of the tank compared to other lower-quality linings. This operation established uninterrupted and dependable flow of 40 USG/D (151.4 L/D) at up to 4,000 PSIG (275.8 BARG) discharge pressure. Additionally, the client had the ability to run both heads at the same time while injecting into one or two injection points independently.

Methanol Package

- Independent dual injection sites

- Resilient “chemflake” coating on tank

- Smaller competitor pumps unreliable