CheckPoint Improves Enhanced Oil Recovery Process

BrightWater chemical and application technology, co-developed by Nalco, BP and Chevron, is applied to water flood during a secondary recovery process to improve oil production. This improvement technology has been successfully established in various parts of the world.

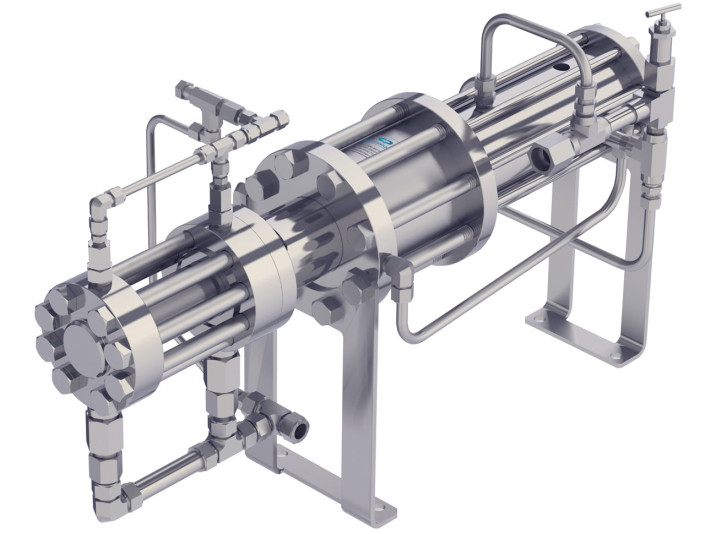

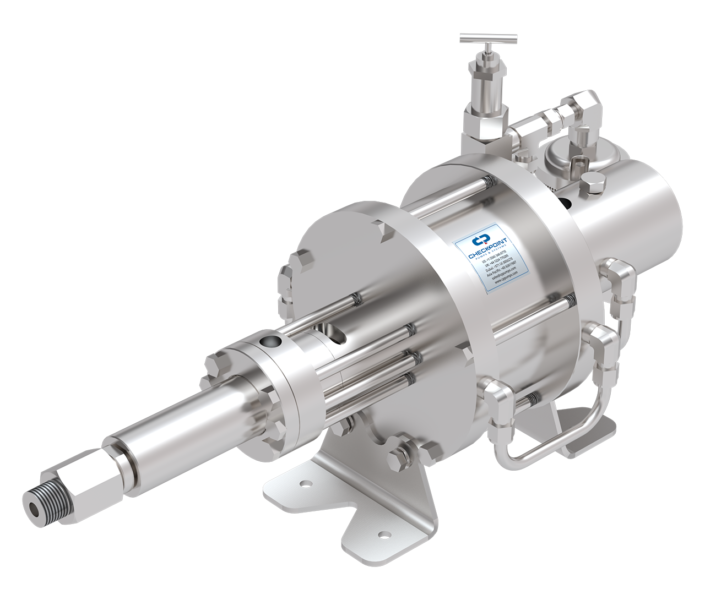

One of the more recent BrightWater projects took place at BP’s Tangri field in Pakistan. The client needed surfactant deployed in order to flush and clean the rock formation; this surfactant had to run in parallel with a high viscose polymer at half the rate for the same duration. CheckPoint Pumps & Systems’ solution came in the form of dual 8428 model pumps, pumping 15,850 gallons (60,000 L) into each well over a period of time at varying pressures up to 1,000 PSIG (70 BARG).

At one point, a large water trap needed to be fabricated in-between the compressors and CheckPoint pumps. The compressors were supplying the air drive to the pumps which were passing water through the hoses and into the air drive of the pump; subsequently, glycol was added to the filter regulator at a few drops per minute to spray a fine mist inside the air head, as lowered nighttime temperatures could cause the spool to freeze.

A further two units have been requested by Nalco for the next water flood location. CheckPoint’s solution contributes to the success of the BrightWater project, known for increasing oil production up to 10%.

EOR Assistance

- Harsh conditions – required dedicated monitoring by CheckPoint support

- Unforeseen issues tackled successfully

- Dual pumps for dual applications