LLOG Exploration Company, a member of the top 10 private oil and gas companies in the US, sought multiple pump solutions to provide a methanol injection.

LLOG Exploration Company, a member of the top 10 private oil and gas companies in the US, (Oil & Gas Financial Journal 2009), sought multiple pump solutions to provide a methanol injection. The harsh conditions found within the Gulf of Mexico’s geography are renowned for increasing the difficulty and importance of any solution deemed acceptable for use on off shore platforms. Unfortunately, over the course of a year, it was realized that all possible pumping solutions reached a point of failure within a period of approximately 24 hours, while attempting to achieve a flow of 24 GPH @ 7,800 PSI.

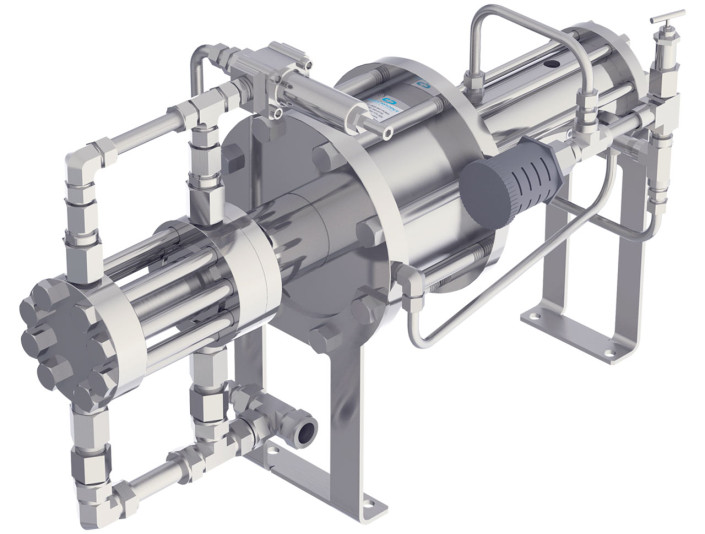

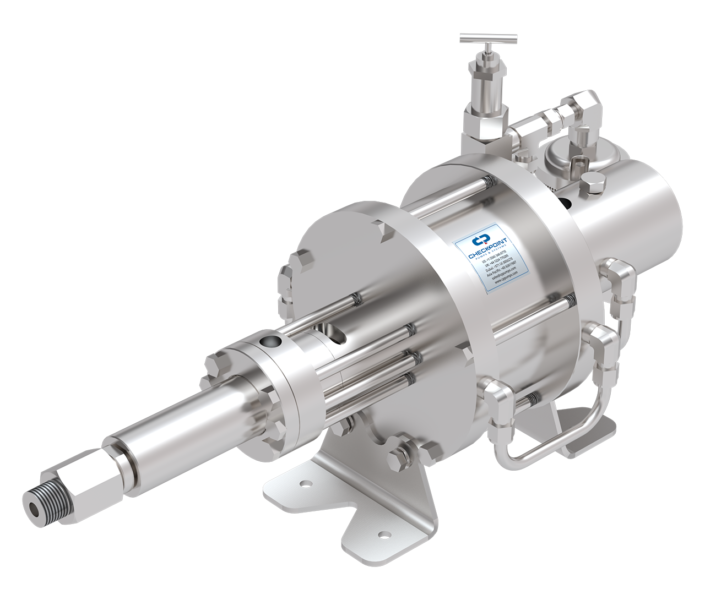

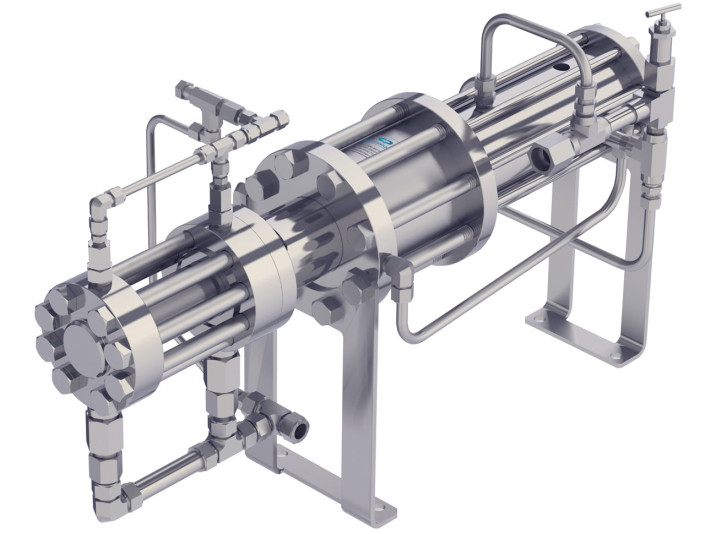

As production delays grew, LLOG made the decision to commission CheckPoint Pumps & Systems. CheckPoint was selected for its history of expertise and success as a provider of reliable and precise chemical injection products. Upon review of the application requirements, two 8412 Series pneumatic pump packages were deployed to the injection site located on LLOG’s Gulf platform, Pompano. Upon installation, LLOG experienced immediate improvement in its desired operation. The packages, paired with

CheckPoint’s engineering support and technical service team, achieved a successful solution. In the days following installation, engineers and technicians were present on the rig to diagnose issues and recommend slight design alterations to achieve optimal performance. CheckPoint’s success was proven while the same results were unattainable for other chemical injection products and their providers.

As a result of CheckPoint’s absolute and non-negotiable commitment to excellence, LLOG saw its downtime decrease and production volume increase dramatically:

- CheckPoint’s engineering and service team provided onsite platform services

- Production previously stifled due to a tough application was corrected

- The Series 8400 pneumatic pump tackled the application within the 40th percentile of its pressure capacity while utilizing less than 12% of its available flow range