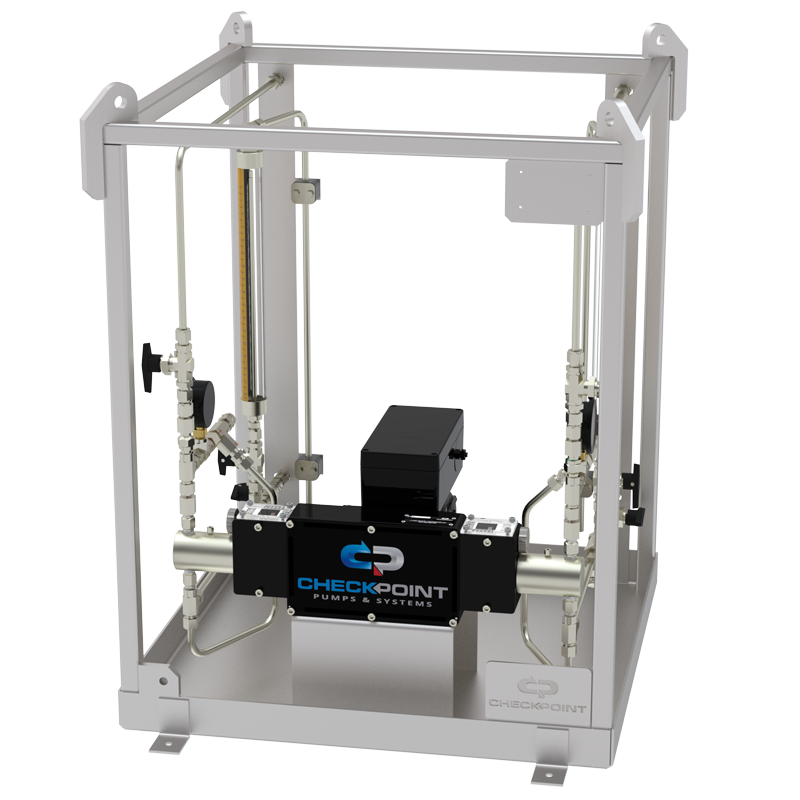

Excellence is the framework for everything we do

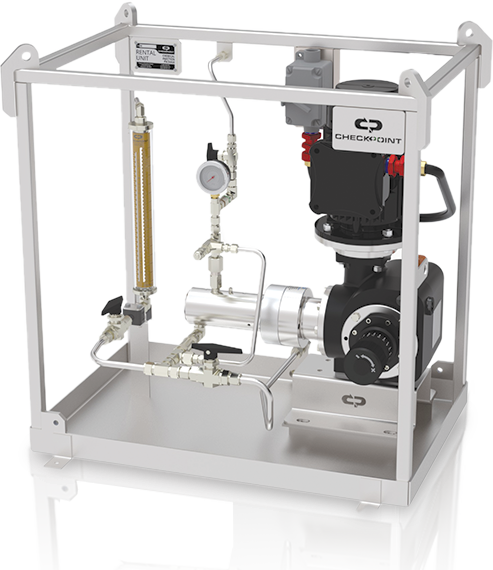

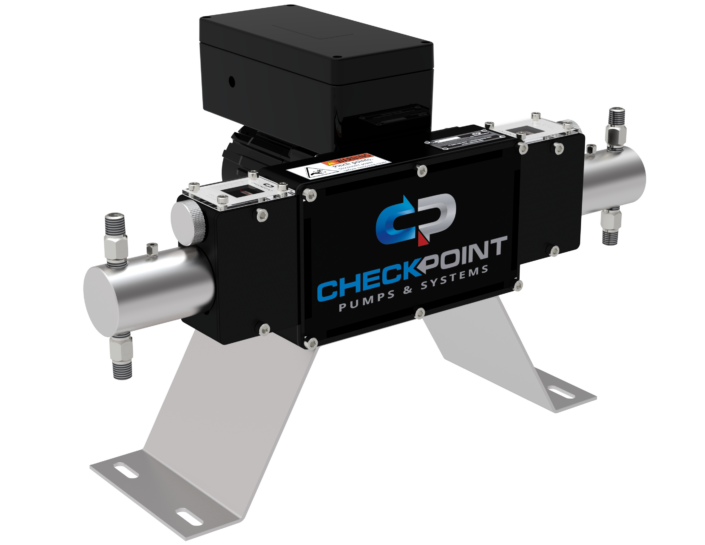

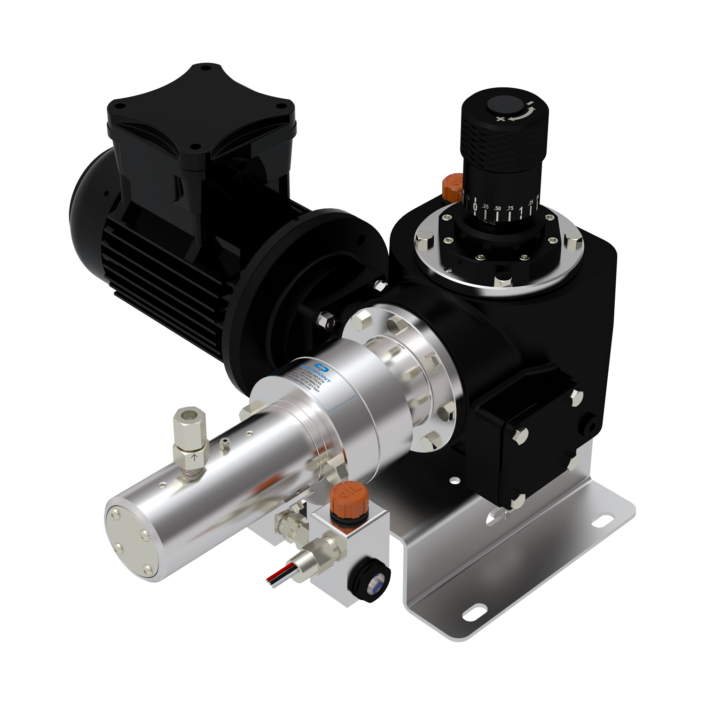

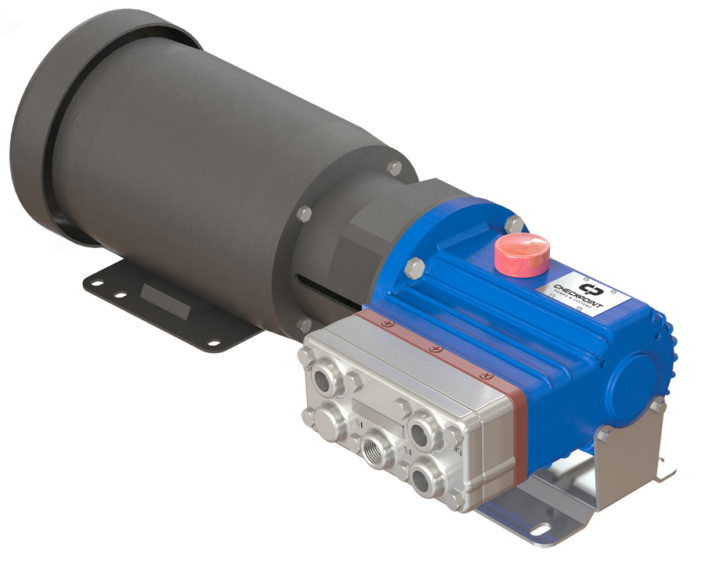

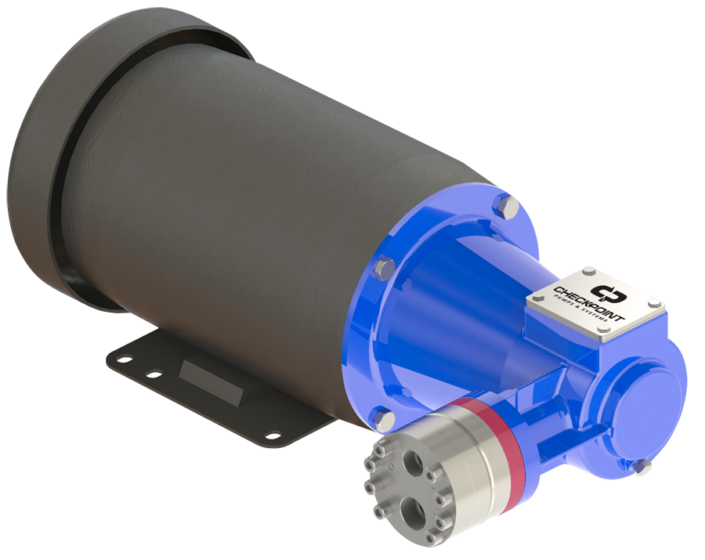

CheckPoint® is a leading provider of chemical injection solutions. We design, manufacture, and market the world’s most reliable pneumatic, electric, and solar chemical injection pumps, along with standard and custom pump packages, control panels, pressure test systems, process components, and green energy solutions.